Case Study

Electronic Paper Tag

Case Study1Eliminate “Kanbans” at manufacturing facilities and drive paperless and DX.

- IndustryCar manufacturing

- Products and ServicesCar parts manufacturing including AC prats

- SKE product used for this project.Electronic Paper Tag

- Implemented inin 2023

Implementation

Implementation

Challenges/Issues

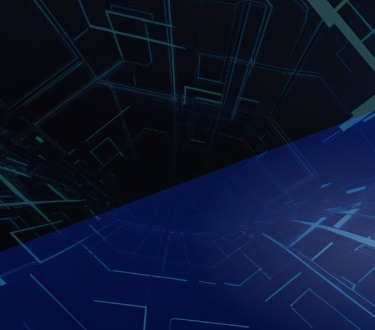

Using “Kanban” system for production process

management.

“Kanbans” with QR code and/or bar-code were re-used, but there were issues with

mis-placed “Kanbans” and increased sorting processes.

Why SKE product was chosen.

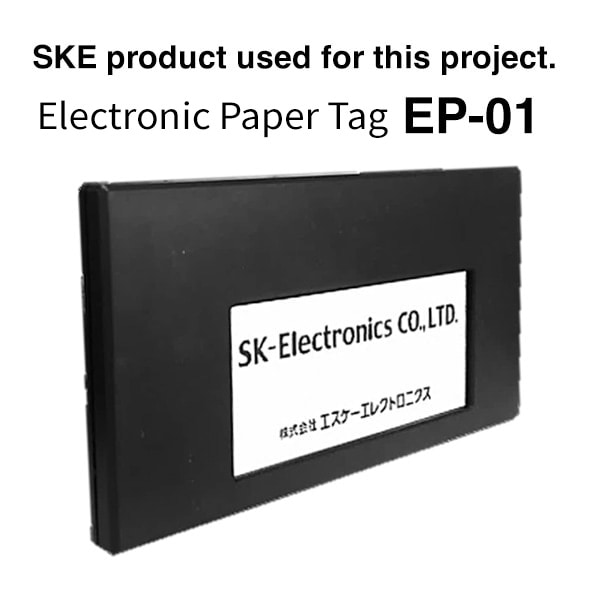

The Electronic Paper Tag can be rewritten many times, and it also allows data to be written when

the tags are stacked, which is very convenient.

No needs to put “Kanban” on and off, and we

thought the Tag could eliminate misplaced “Kanbans.”

After its

implementation

After its

implementation

How the issue was solved and its procedures.

Outcomes

By switching from “Kanban,” which was paper based, to the Electronic Paper

Tag, we could eliminate paper.

We were freed from sorting “Kanbans” and misplacing them, and

we have gained more than what we paid for the Electronic Paper Tag.

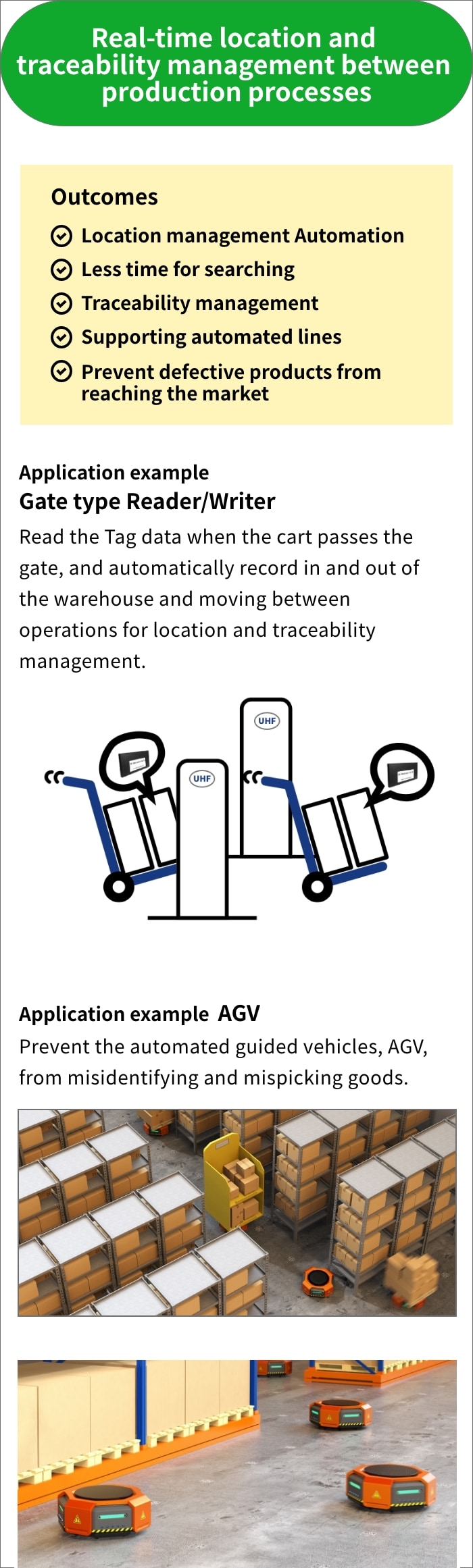

Case Study2Easily locate goods in process as they move between processes at a glance.

- IndustryCar manufacturing

- Products and ServicesCar parts manufacturing

- SKE product used for this project.Electronic Paper Tag

- Implemented inin 2023

Medical Equipment manufacturing, sales, and import/export.

Implementation

Implementation

Challenges/Issues

- The paper based work instruction has been made paperless.

- Real-time production progress management for each production process

Why SKE product was chosen.

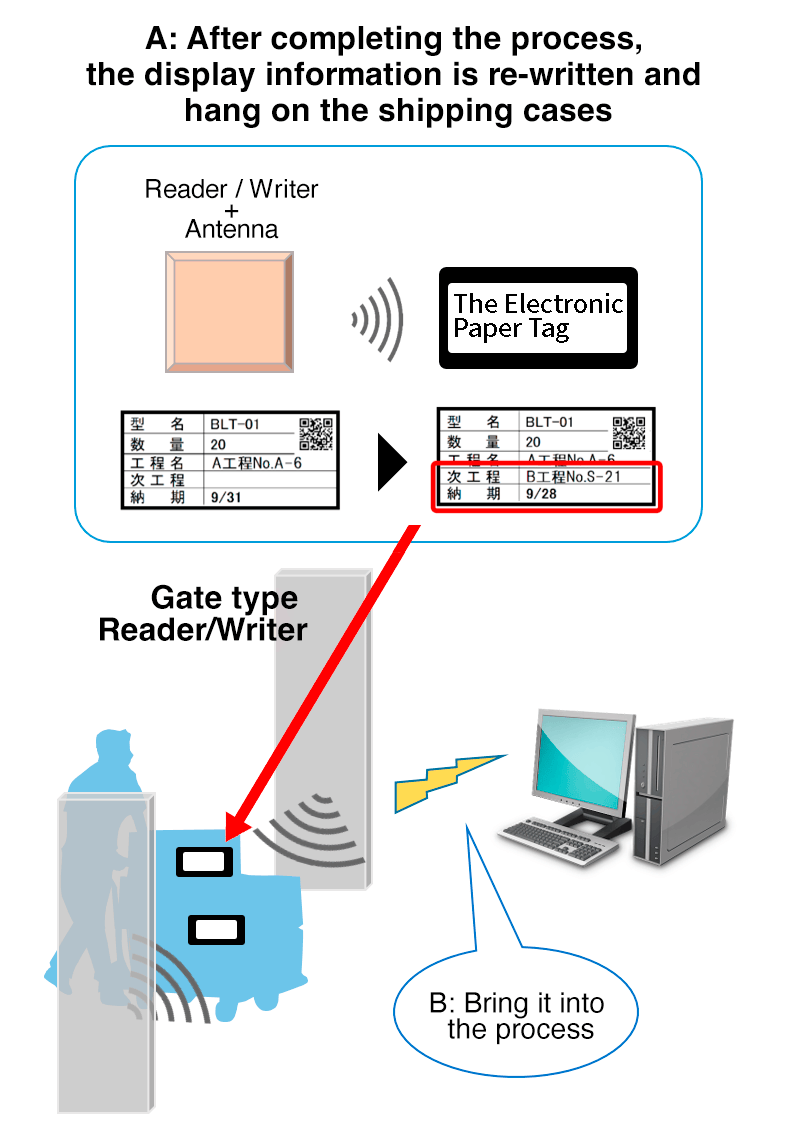

The Electronic Paper Tags on the products enabled realtime location, production processes, management as the readers/writers installed at the gates between operations read the tag information.

After its

implementation

After its

implementation

How the issue was solved and its procedures.

Outcomes

- The paper based work instruction has been made paperless completely.

- The Electronic Paper Tags on the goods in process enabled realtime location, production processes, management as the readers/writers installed at the gates between operations read the tag information.

- Simplify the management of defective products and prevent them from reaching the market

Voice of Customer

Improved overall work efficiency by eliminating paper based work instructions that were replaced by the Electronic Paper Tag, and it enabled process and product location management.

SKE Sales person

The Electronic Paper Tag makes it possible to go paperless and manage

process/location/traceability.

We were able to provide the best solution for the customer.

SKE Sales person

The large number of “Kanbans” has been made paperless, and it is also possible to reduce some operations by implementing the Electronic Paper Tag.

We can provide solutions for DX and automations like this case.