Case Study

Solution

Case Study1Easily locate transporting carts at a glance.

- IndustryManufacturing Industry

- Products and ServicesElectronic parts

- SKE product used for this project.Proposed a solution that was a combination of RFID products from other manufacture and SKE.

- Implemented inIn 2023

Implementation

Implementation

Challenges/Issues

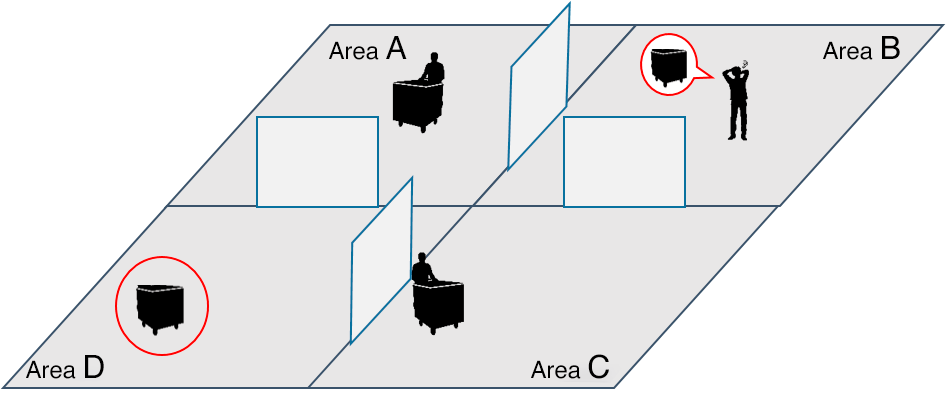

The specified carts with production materials move back and forth between the production areas in

the cleanroom.

The location of these carts and their operating status were recorded in an

excel format, but oftentimes could not find these carts location and spent some time for

searching them as some missing information on it due to human errors.

Why SKE product was chosen.

For the beginning, installed a wireless device on a cart and conducted location tests. However,

the device’s communication range was wider than expected, and it could not locate the carts.

“Locating the carts” was the challenge that needed to be solved, so we abandoned it.

Then

switched to RFID technology.

After some tests, the location information was collected and

managed as expected, so we decided to implement the Tag.

After its

implementation

After its

implementation

How the issue was solved and its procedures.

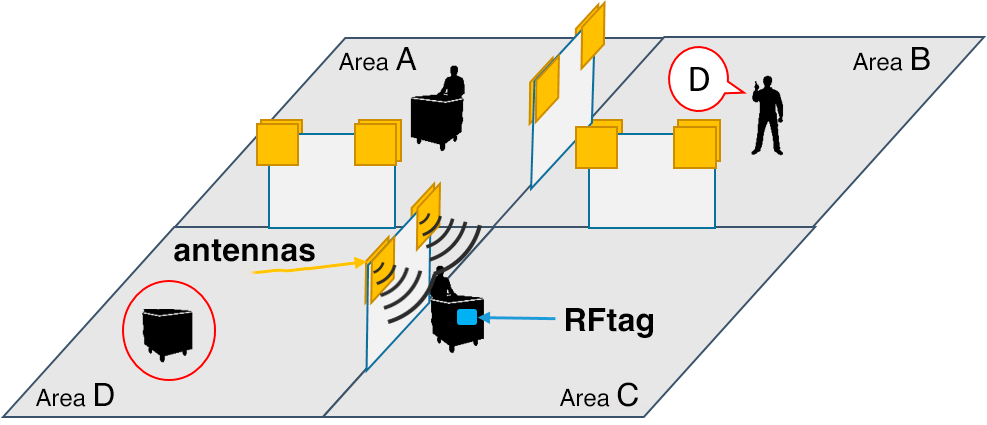

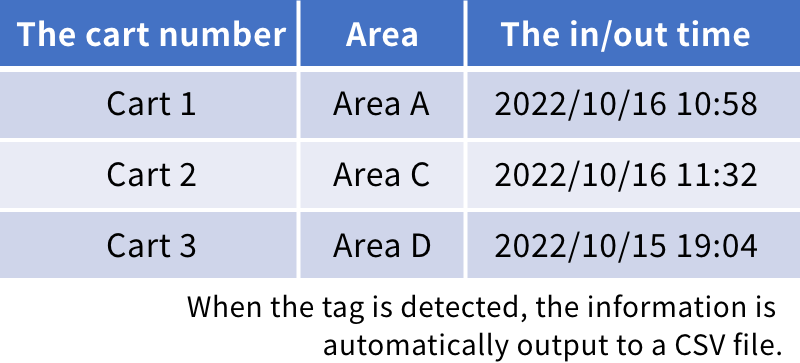

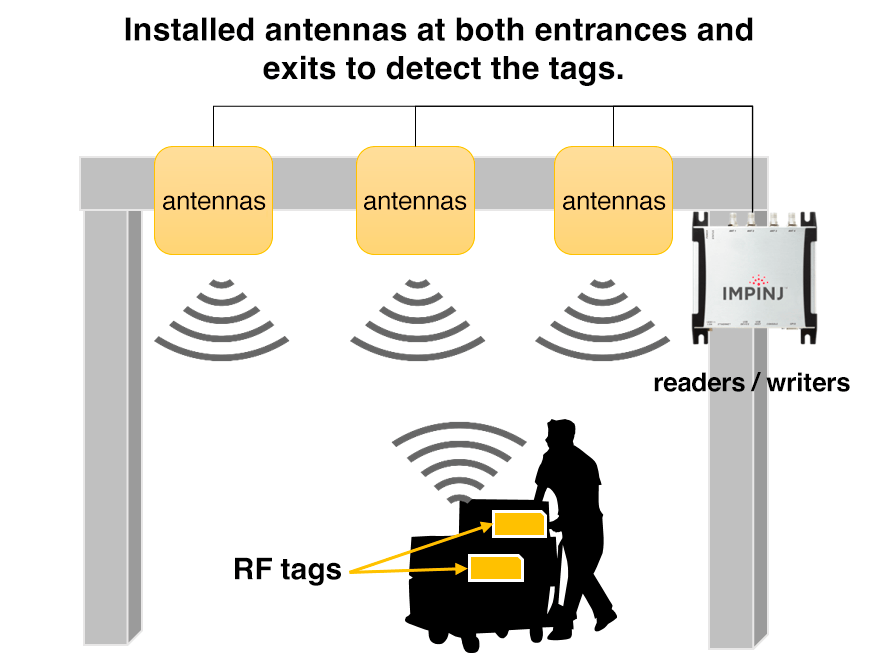

Installed the readers/writers and antennas at the doorways to each area. When the carts with the tags pass through these doorways, the tags can be detected and recorded the in/out time and the cart number. Available carts are located easily.

Outcomes

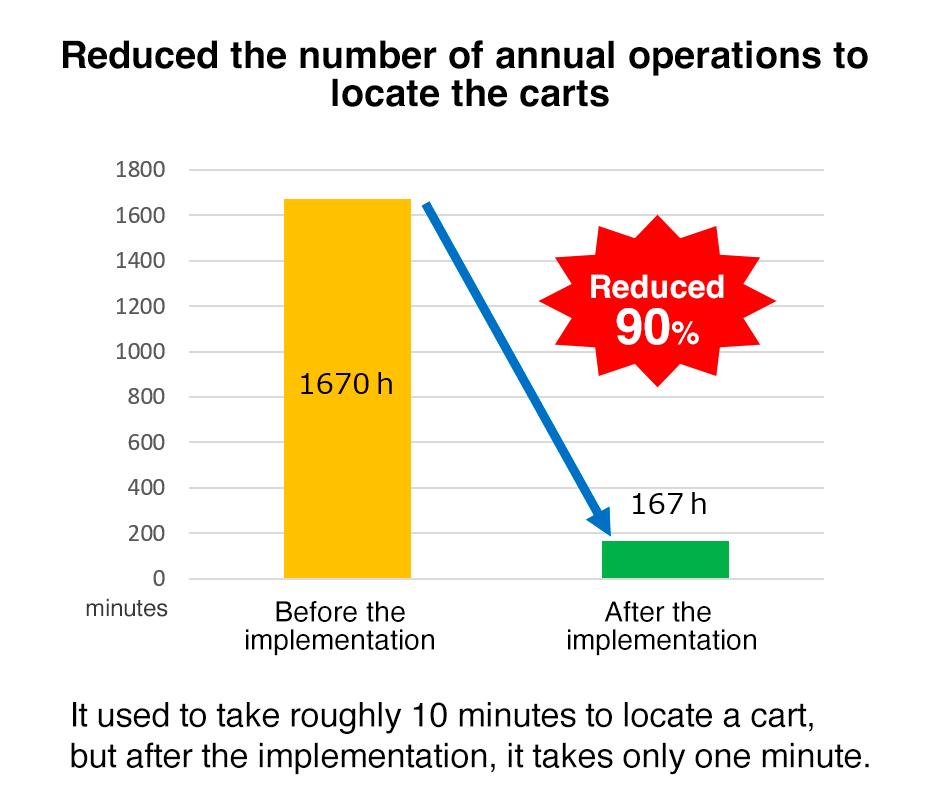

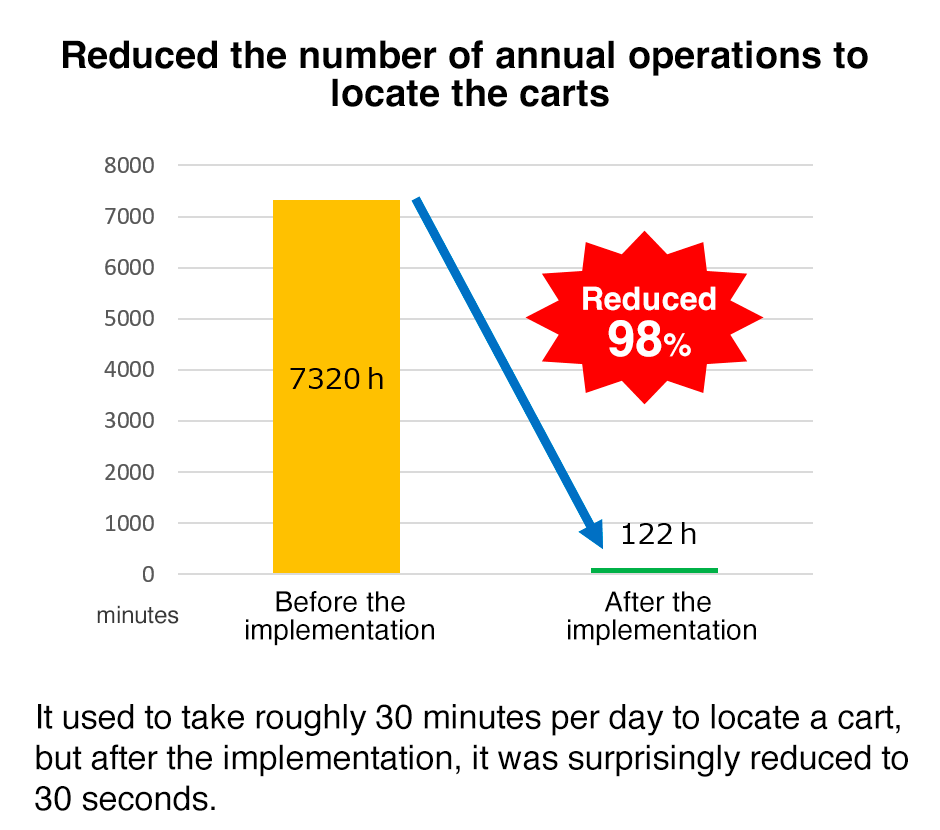

Not only did it improve the operational efficiency by reducing the search time, but it also improved the operators’ mindset that made them realized that it was possible to improve operational efficiency with a system implementation.

Voice of Customer

We are very much satisfied with the RFID implementation. We reduced the search time, improved

operational efficiency and 3M “Kaizen,” and cost reduction through improved operational

efficiency.

The simple and affordable pricing proposal was very attractive to us as we just

wanted the information on “where the carts are”.

Now we are thinking about utilizing the

system other than the cart management.

Case Study2Smart location mapping!

Smart inventory control!

- IndustryThe manufacturing industry

- Products and ServicesElectronic components

- SKE product used for this project.The solution combined with other manufacture’s RFID tags and SKE’s.

- Implemented inin 2023

Implementation

Implementation

Challenges/Issues

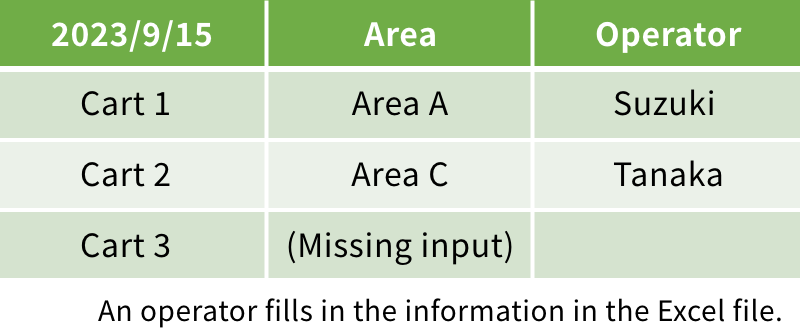

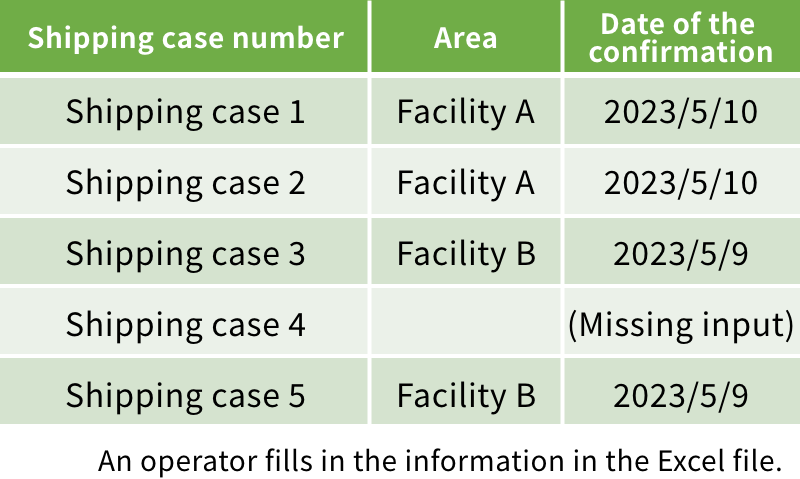

Shipping cases with production materials go back and forth between two warehouses.

Operators visually confirm the number of these cases at their location and record it into an

Excel file.

However, oftentimes, these cases are unable to be located as some missing

information on the file due to human errors.

Want to have the management of the case location

completely.

Why SKE product was chosen.

We have implemented the RFID system for the cart management, and we thought we could use it for other purposes.

After its

implementation

After its

implementation

How the issue was solved and its procedures.

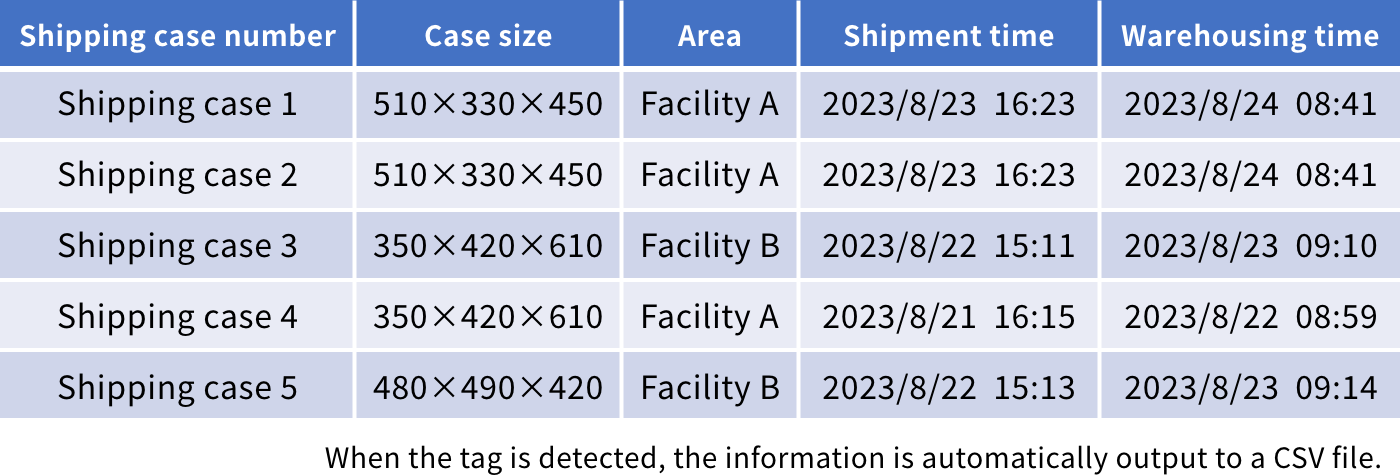

Installed antennas at the warehouse entrances and exits, and when the shipping cases are in/out

the warehouses the tags on the cases are detected.

The case number, in/out time, the case

size and necessary information can be viewed in both warehouses.

Outcomes

Almost zero missing shipping cases as the in/out logs are recorded at both

warehouses.

Operators are just going under the antennas as they have been doing in the past,

with no additional action required. Yet their workload was reduced as they no longer had to

input information into the Excel file.

In addition, the case usage analysis and its

replacement timing information are available as looking at past logs.