Case Study

Picking Tag

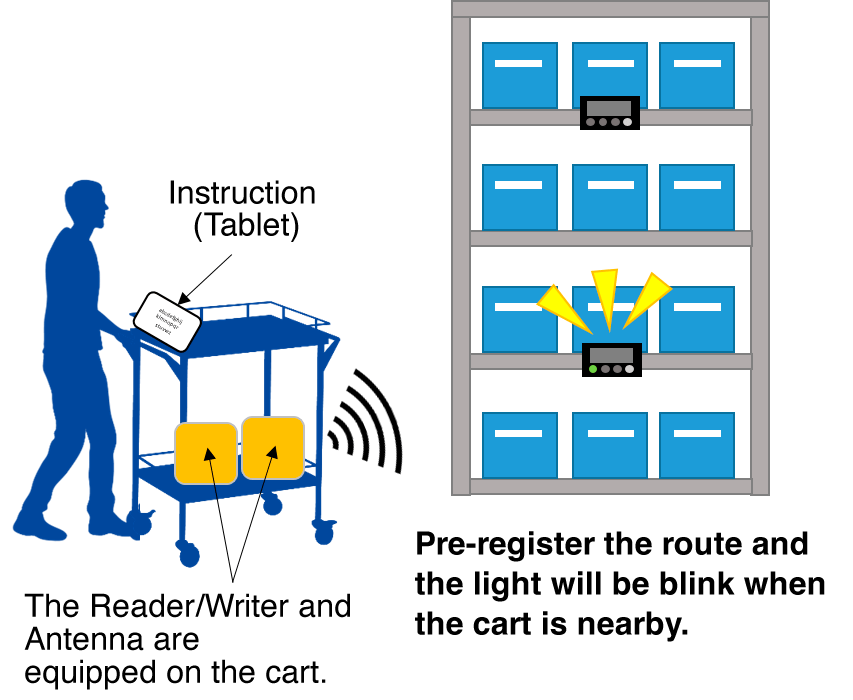

Case Study1Combination of picking carts and multiple light colors improves in-out warehouse operation efficiency!

- IndustryMedical equipment manufactures

- Products and ServicesMedical equipment

- SKE product used for this project.Picking Tag

- Implemented in2022

Implementation

Implementation

Challenges/Issues

In the warehouse, mis-sorting occurred oftentimes as there were a lot of similar parts that were

visibly unrecognizable.

Needed the system can be easily followed without deep knowledge and

experience in order for the customer to standardize the warehousing processes.

Why SKE product was chosen.

We manufacture various kinds in small quantities of products, and we were looking for wireless

picking tags.

Also SKE’s are equipped with solar batteries so that no battery changes are

required and less hassle, which was one of the key factors for us to implement SKE’s tags.

After its

implementation

After its

implementation

How the issue was solved and its procedures.

Outcomes

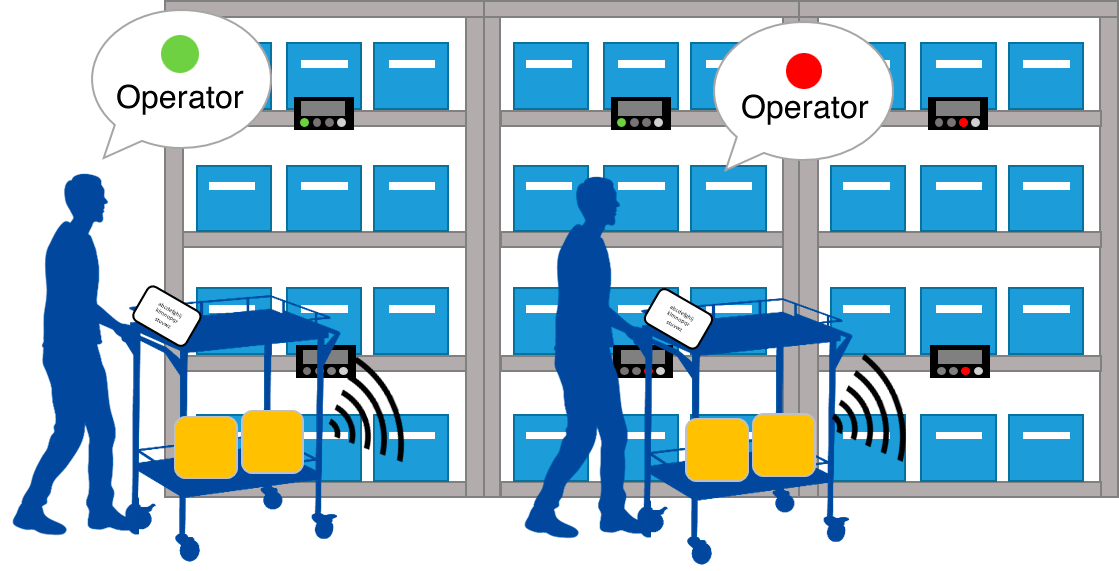

Able to use both hands as the reader/writer and antenna are on the cart. No

confusions while working with multiple operators as there are 7 light patterns.

Picking time

was reduced. Instead of visually search the parts, lights notify which part needs to be picked

in the efficient order.

Almost no picking mistake, and it leaded to production efficiency

with improving working environment.

SKE Sales person

By implementing our wireless picking tags, the operation has been standardized and streamlined, and new employees can easily work on the picking operation.